You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gunters new octocopter build

- Thread starter Gunter

- Start date

Looking good Gunther

The assembly after designing is always the fun part!

Until you find that problem you didnt see before that is!

Im not sure if you have said before but what are the specs of your motors?

Do you know what the all up weight will be including the camera mount and camera of your choice?

What is the camera you will be using by the way?

Many thanks

Ben

The assembly after designing is always the fun part!

Until you find that problem you didnt see before that is!

Im not sure if you have said before but what are the specs of your motors?

Do you know what the all up weight will be including the camera mount and camera of your choice?

What is the camera you will be using by the way?

Many thanks

Ben

Gunter

Draganflyer X4

Im not sure if you have said before but what are the specs of your motors?

Do you know what the all up weight will be including the camera mount and camera of your choice?

What is the camera you will be using by the way?

Many thanks

Ben

Ben, motors are cheap 880kv Arducopter motors. I will upgrade sometime, but I didn't want to spend a fortune at the moment. I'm not sure of the exact weight yet, I'll weigh it when it's all together. Airframe alone is around 1kg though, or so the computer says! Camera will probably be an NEX5 or similar...

Looking good.. where did you get the rubber dampers from?

Dave

http://www.bpfittings.co.uk/pc/Twin-Male-Anti-Vibration-Mounts-c10815.htm

They are pretty cheap, I think £1.50 ish, so worth getting a few spare!

Gunter.

Gunter

Draganflyer X4

Attachments

Gunter

Draganflyer X4

Thanks Droider, my "suprise" landed in the post today...the new DJI brain.

View attachment 1087

Mocking up to see sizes:

View attachment 1088

From the top:

View attachment 1089

The LED unit:

View attachment 1090

Supporting the South Africans in the rugby:

View attachment 1091

View attachment 1087

Mocking up to see sizes:

View attachment 1088

From the top:

View attachment 1089

The LED unit:

View attachment 1090

Supporting the South Africans in the rugby:

View attachment 1091

Attachments

Gunter

Draganflyer X4

Attachments

Gunter

Draganflyer X4

I'm liking the South African support right there!

The hexa is looking very awesome! Could I ask what thickness sheet and alloy you used?

Thanks Orracle! I'm from Hillcrest, near Durbs, hence the SA support!

The aluminium is all 2mm except for the bottom round plate which is 3mm. It all seems sturdy enough, the final test is when it flies!

Gunter.

Orracle

Member

Haha that's cool! I work for a laser cutting company just down the hill from Hillcrest in Westmead  I just laser cut a small quad copter frame for myself, posted pics in the Newbie intro forum.

I just laser cut a small quad copter frame for myself, posted pics in the Newbie intro forum.

Hopefully I get into AP and can take some pics of your old area, I reckon valley of a thousand hills would be pretty awesome to fly in

Hopefully I get into AP and can take some pics of your old area, I reckon valley of a thousand hills would be pretty awesome to fly in

Gunter

Draganflyer X4

Haha that's cool! I work for a laser cutting company just down the hill from Hillcrest in WestmeadI just laser cut a small quad copter frame for myself, posted pics in the Newbie intro forum.

Hopefully I get into AP and can take some pics of your old area, I reckon valley of a thousand hills would be pretty awesome to fly in

I used to work at Smiths Manufacturing on the other side of Pinetown, not sure if you have heard of them?

Valley of a thousand hills would be superb to take pics of, there is also the Kloof gorge, a few places in Hillcrest as well. There is a big community with a castle, lakes and a gold course, that would also be a good one for pics.

I'm hopefully going to be out there this time next year, I will bring the heli along and do loads of video. Plans are to stay at Midmar for a while, then South Coast and Hillcrest...might be a good opportunity for a SA meet!!

Gunter

Draganflyer X4

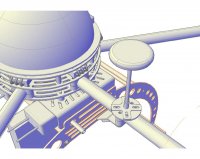

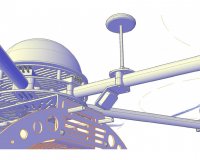

Quick update: Just waiting for a few more ali parts before I can send the whole lot for powder coating. I mocked up the center plates and booms, which all fit nicely. Boom clamps should be here next week, so then everything will be ready for final assembly! All up weight is just over 2kg.

View attachment 1165

I modelled a bracket for the GPS and LED. They both need a special place to go, otherwise they will look a bit left out!

View attachment 1167 View attachment 1166

Hopefully everything will be done and together for the meet at the end of the month...fingers crossed!

View attachment 1165

I modelled a bracket for the GPS and LED. They both need a special place to go, otherwise they will look a bit left out!

View attachment 1167 View attachment 1166

Hopefully everything will be done and together for the meet at the end of the month...fingers crossed!

Attachments

Gunter

Draganflyer X4

Ye I know of Smiths Manufacturing, we laser cut alot of brackets for them

An SA meet in a year! I better start flying and start up a mrc community quick then!

Haha, yes, get the banana boys together with their quads!

I just have to figure out a way to transport this thing now...it certainly won't fit in the baggage hold like it is now!

Quick update: Just waiting for a few more ali parts before I can send the whole lot for powder coating.

Hey Gunter

Why powder coating and not anodizing?

Orracle

Member

Haha, yes, get the banana boys together with their quads!

I just have to figure out a way to transport this thing now...it certainly won't fit in the baggage hold like it is now!

Haha, I would be very nervous trusting the baggage handlers with such an expensive bit of kit.

Regarding the powder coating, I also gotta ask the same question as Borneoben, why not anodizing? It adds no weight as opposed to powder coating which can add 10g/m^2, according to google

I was concerned not so much for the weight but tightening screw heads against the relatively thick coating could make it crack and lift off?

with anodizing you wouldnt have that???

We used to powder coat the chassis of kit cars and if the coating was too thick it would alwasy lift around sharp edges and when you drilled through it and when you tightened a bolt against it. even with washers etc.

Ben

with anodizing you wouldnt have that???

We used to powder coat the chassis of kit cars and if the coating was too thick it would alwasy lift around sharp edges and when you drilled through it and when you tightened a bolt against it. even with washers etc.

Ben