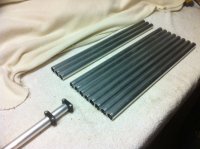

Looking good!

I've researched this "ESC wires" issue as thoroughly as possible. Trouble is, of course, that you can find reasoned, scientific arguments both ways! However, after weighing all the evidence, my conclusion is to keep battery > ESC short and ESC > motor can be lengthened to suit your frame.

I, too, detest the idea of strapping the ESCs to arms. It looks ugly, plus they're vulnerable to damage and subject to all the vibration that's travelling through that arm. I also don't go with the argument that they need to be cooled by the propwash. If they need that much cooling then they're either under-rated for the job or something else is wrong (like the timing). The best advice I've seen on ESC sizing (by a dealer who has to field warranty claims for burned out ESCs) is to over-spec by 50%, i.e. if eCalc says your full-throttle draw will be 37A, fit 60A ESCs - not 40A units.

Of course the ESCs still need airflow, so certainly don't put them inside a box (which I've seen done). If you do have a minor heat issue and/or want more peace of my mind over their health and longevity, fit each one with one of those miniature fans used on PC motherboards - they weigh just a couple of grams.

One thing I believe you should NEVER do (on anything but the small fun-flyer types) is use the BEC on the ESC. They're often linear BECs on the cheaper ESCs (which simply drop voltage by using resistance and therefore generating heat), and since you'd only be using the BEC on one out of your 4, 6 or 8 ESCs that ESC will run hotter than the others - not a good design choice. A good quality switching BEC can supply all the necessary low voltage to your FC, Rx, servos, etc.