jbrumberg

Member

I do all my battery charging indoors under supervision in a relatively fireproof area. I have been storing all my LiPo's and LiFe's batteries indoors at either discharged states or storage charge states in a metal box. I was storing them in my wood stove, but that is in use this time of year. I may keep a couple of 1S LiPo's charged and ready for action if I anticipate use in the near future. I do not think these Li types of batteries would tolerate storage in the outdoor temperatures typical of a New England (USA) winter. An idea I read about involved storing batteries in a metal canister such as yours and having a bag of sand resting on top of the batteries so if in the event of a fire the plastic bag containing the topping sand would melt causing the sand to smother the burning LiPo batteries. LiPo batteries really do not need an additional air supply to burn. What one needs to do is contain the fire.

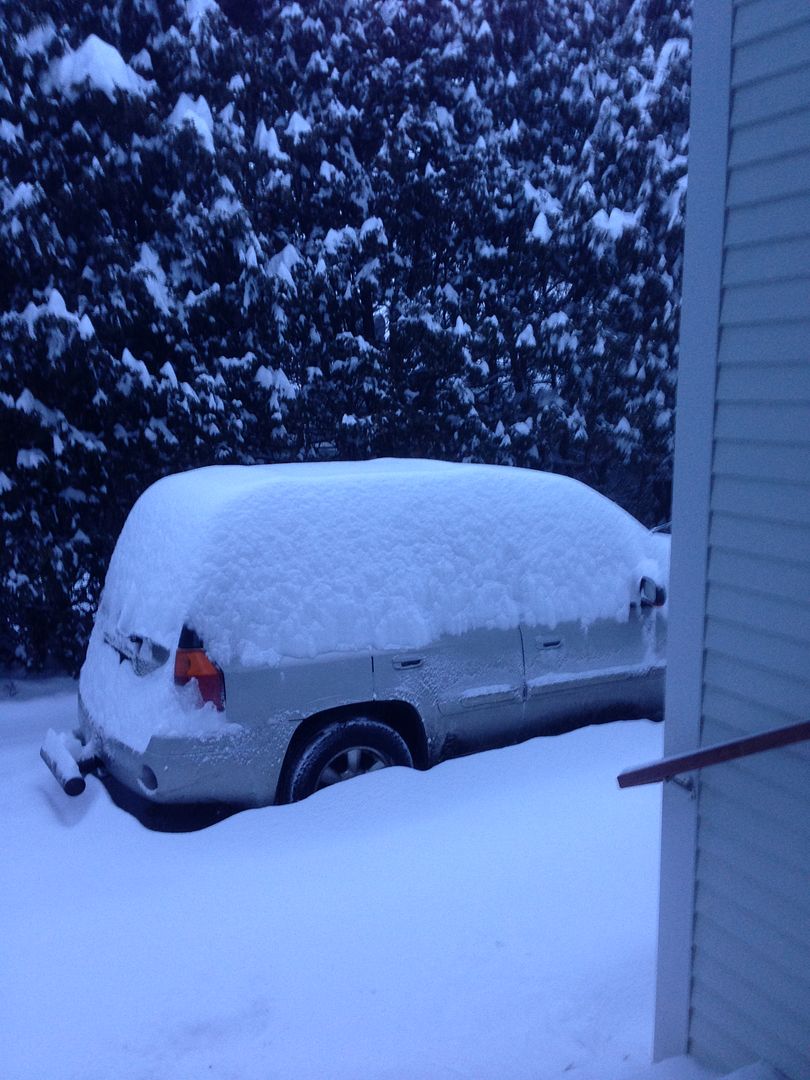

PS: We got 8" of snow here with the sleet topping down here.

PS: We got 8" of snow here with the sleet topping down here.