You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wookong-M on a RC-Carbon 900 mm boom

- Thread starter BorisS

- Start date

BorisS

Drone Enthusiast

Jess111 i am using the axi 2820 for now might go a step higher with the motors afterwards if the DJI really performs this good. I was scared that motors drawing around 40a plus at max would have an issue with just wiring so i wanted a solid core ring like Mactadpole did it. And i was convinced by the cleanness of the setup

BorisS

Drone Enthusiast

left to add the the 2.3 KG

DJI WK-M 150g

ECSs 6x 33g 198g

more wiring 100g

I end up with 2748g

Plus Av 200 let say 590g

I end up with 3338g

About 134 heavier than my AD8 with the same setup hmm not good.

Only difference is the motors: AXI 2814/20 on the AD 8 105g total 840g

AXI 2820/14 on Rc Carbon 151g total 906g

diff 66g

Hexa heavier than the Octo, gonna start checking out the frame and reduce or change parts

DJI WK-M 150g

ECSs 6x 33g 198g

more wiring 100g

I end up with 2748g

Plus Av 200 let say 590g

I end up with 3338g

About 134 heavier than my AD8 with the same setup hmm not good.

Only difference is the motors: AXI 2814/20 on the AD 8 105g total 840g

AXI 2820/14 on Rc Carbon 151g total 906g

diff 66g

Hexa heavier than the Octo, gonna start checking out the frame and reduce or change parts

Wayne Jones

Member

Power distrobution

Just for ideas here are some pictures of my Droidworx Cinema Series-C6 hexacopter power distro build. It was an easy solder job is compact and seams to work quite well. I have already had to replace a couple of esc's. It is pretty easy with a good soldering iron. That self blending tape you are thinking of goes by the name of "Rescue Tape". Just Google it.

View attachment 885 View attachment 886 View attachment 887

View attachment 888 View attachment 889

Just for ideas here are some pictures of my Droidworx Cinema Series-C6 hexacopter power distro build. It was an easy solder job is compact and seams to work quite well. I have already had to replace a couple of esc's. It is pretty easy with a good soldering iron. That self blending tape you are thinking of goes by the name of "Rescue Tape". Just Google it.

View attachment 885 View attachment 886 View attachment 887

View attachment 888 View attachment 889

Attachments

BorisS

Drone Enthusiast

Hi Wayne, looks good im going to check how simple it is for me to get a cooper ring like that I want to have the setup finished this weekend, if the ESCs still arrive today, otherwise the rest should be done and ready for them.

The DJI just arrived, probably heard it before but the unit is really small !

View attachment 891

The DJI just arrived, probably heard it before but the unit is really small !

View attachment 891

Attachments

Last edited by a moderator:

BorisS

Drone Enthusiast

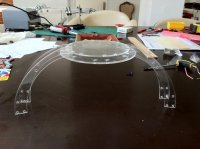

and my prototype dome / roll-cage arrived for this build. Kept it in acrylic for test if my measurements were correct, will probably be out of carbon later, since the gps will be mounted over it anyways.

View attachment 892

View attachment 892

Attachments

Emowillcox

Member

Hey Boris your build is looking nice. I see your concerned about the weight. Is this your first RC carbon frame? How does the weight of the RC carbon frame compare to others?

I like that idea of the copper washer. I guess you could find such a thing at a plumbing store, but I see also that Misumi does them in any size/thickness you want (love that place!). Interestingly, to get the 6mm^2 you'd need, the washer can be amazingly small: 4mm ID, 10mm OD and 1mm thick would give you 6mm^2 cross-sectional area. Of course, your solder is going to supplement that, so definitely no problem handling the current even with the smallest washer you can find.

This has got me thinking what I can produce with sheet copper on my CNC, which finally arrives next week

This has got me thinking what I can produce with sheet copper on my CNC, which finally arrives next week

Mactadpole

Member

Hey Boris,

The trick with the distro ring with deans is to make the circle as small as possible and just use one piece of solid wire around. I think since yours looks to be fairly big in diameter and has the braided wire you have added a lot of weight.

I agree the aren't necessary for every application but they are very nice for folding frames such as the RC-Carbon because you can just unplug to fold the arms instead of having a ton of extra wires. This type of distro ring is also nice if you have a frame where you want to be able to remove arms for easy transportation. Those are the main reasons I make my distro rings with the deans.

Shawn

The trick with the distro ring with deans is to make the circle as small as possible and just use one piece of solid wire around. I think since yours looks to be fairly big in diameter and has the braided wire you have added a lot of weight.

I agree the aren't necessary for every application but they are very nice for folding frames such as the RC-Carbon because you can just unplug to fold the arms instead of having a ton of extra wires. This type of distro ring is also nice if you have a frame where you want to be able to remove arms for easy transportation. Those are the main reasons I make my distro rings with the deans.

Shawn

BorisS

Drone Enthusiast

@ japp I agree Mactadpole that was also my idea or reason why i copied you to keep the plug unplug possibility. But i am gonna go for a hunt now for the cooper ring and combine the ideas.

@ Emo i will weigh it later on today and post. Did not write done my results. I remember though that they are heavier than DW frame by a bit. One reason do to the amount of screws and than compare to a standard HL their booms are 21mm by 17mm. But he also uses parts in the lading gear that are unnecessary. In the DW frame the landinggear and its gear rail tubes are carbon and plastic inside with the screw thread. RC Carbon or Coptersky whatever have a (hope that the right english word) carbon tube with a metal gear thread pole inside. Makes it heavier and in case of a harder handing the DW gear rails brake (which is good) but with the RC Carbon i am sure the actual landinggear frame will be hurt by the metal gear rail. Otherwise its a solid good frame with the plus of the folding. The booms have little surface imperfections but i don't really care. I also consider the slidin slideout lipos trays as unnecessary parts and screws weight again, plus i prefer the have the lipos on the ladinggaer instead of the centerplates. Again harder lading i dont want to stress on the canterplates with the electronics on. But this could turn out to be past times considering DJI being much more robust with its casing than any MK electronics and the casing is not really screwed thus prone to brake if the centerplate does.

@ jess i think once you have your cnc you should be sharing the parts you create ! Everyone is going to hold themselves back from asking you to send out a copy of the parts, i am sure

Boris

@ Emo i will weigh it later on today and post. Did not write done my results. I remember though that they are heavier than DW frame by a bit. One reason do to the amount of screws and than compare to a standard HL their booms are 21mm by 17mm. But he also uses parts in the lading gear that are unnecessary. In the DW frame the landinggear and its gear rail tubes are carbon and plastic inside with the screw thread. RC Carbon or Coptersky whatever have a (hope that the right english word) carbon tube with a metal gear thread pole inside. Makes it heavier and in case of a harder handing the DW gear rails brake (which is good) but with the RC Carbon i am sure the actual landinggear frame will be hurt by the metal gear rail. Otherwise its a solid good frame with the plus of the folding. The booms have little surface imperfections but i don't really care. I also consider the slidin slideout lipos trays as unnecessary parts and screws weight again, plus i prefer the have the lipos on the ladinggaer instead of the centerplates. Again harder lading i dont want to stress on the canterplates with the electronics on. But this could turn out to be past times considering DJI being much more robust with its casing than any MK electronics and the casing is not really screwed thus prone to brake if the centerplate does.

@ jess i think once you have your cnc you should be sharing the parts you create ! Everyone is going to hold themselves back from asking you to send out a copy of the parts, i am sure

Boris

Wayne Jones

Member

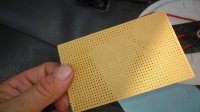

Hey for those who are interested in the copper washer distro harness. Harbor Freight Tools in the US sells a box of assorted copper washers for $7.00. Here are some more photos. I used bare pcb board or plastic to separate the + and - sides then wrapped the whole unit with rescue tape.

Attachments

BorisS

Drone Enthusiast

Wayne thanks for sharing this, I am getting close to something similar just couldnt get the copper ring at any stores close. I think ill have a second round to this build were i am going to change things i already would have liked to change now, but for now i want to get this birg flying beginning of the coming week

Boris

Boris

Wayne Jones

Member

I look forward to the finished product. These aircraft are cool. I onced poo pooed them because I was a heli guy and I didn't understand them but I really see a place for them now and feel that they are here to stay whether it is sport flying or professional.

BorisS

Drone Enthusiast

in the whole town (vienna) I wasnt able to get any 6mm silicon cable great so I had to finish up the dist. ring with 4 mm. For testing it will be fine later gotta change it again great !. The roll cage actually works out have to tweak it now a little and make it more robust. To bad it cant stay in acrylic actually doesn't look to bad.

I will have to mount the GPS modul higher, what i heard from Ken s testing. Which is to bad would have been cool right on top.

View attachment 901View attachment 902

I will have to mount the GPS modul higher, what i heard from Ken s testing. Which is to bad would have been cool right on top.

View attachment 901View attachment 902

Attachments

BorisS

Drone Enthusiast

okay enough of this for this weekend. WK-M unbricked or whatever it was. Just waiting for the ESCs to arrive and to figure the last TX stuff out. Hope the GPS module is mounted away from the IMU far enough and that there is no issue if the IMU and MC are close together.

I am really not such a friend of the GPS module and LED sharing a cable or having this T plug whatever its called. For me it obvious that the GPS module tends to go somewhere to the upper side of the copter and the LED somewhere close to the landing gear. Now i have this connection piece/T plug somewhere in the air and cant really do anything with it.

Boris

View attachment 908View attachment 907

I am really not such a friend of the GPS module and LED sharing a cable or having this T plug whatever its called. For me it obvious that the GPS module tends to go somewhere to the upper side of the copter and the LED somewhere close to the landing gear. Now i have this connection piece/T plug somewhere in the air and cant really do anything with it.

Boris

View attachment 908View attachment 907

Attachments

BorisS

Drone Enthusiast

okay i couldnt stop, started configuring the WK-M and i have a basic TX problem. I dont know to much about the Graupner 22 MX setup and heli mode etc. But everything works except giving the FC a forward and backward command also results in a yaw input for the FC. Does one of you know why these are linked and were I can deactivate this ?

Vid

http://sprealinvest.at/mx22.mov

Boris

Vid

http://sprealinvest.at/mx22.mov

Boris

Flying Tivo

Member

What type of heli setup do you have? H1 H3 HR3.. etc?

It needs to be set to H1 or pure inputs!!

Felipe

It needs to be set to H1 or pure inputs!!

Felipe