BorisS

Drone Enthusiast

Hi,

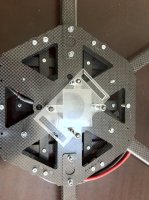

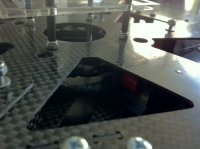

since i decided to use the WK-M on my new system gonna build up the thread about it here.

Following frame:

View attachment 836

View attachment 837

View attachment 838

View attachment 839

gonna cnc some carbon plates to mount the MC and IMU, and LED. To stay in the tower format hoping thats gonna give me enough space to mount the ESCs on the center-plate.

View attachment 840

Specs:

Axi 2820/14

Turnigy Plush 40A ESC

Graupner 22 mx with 35MHz Module back in

SCM 16 Graupner.

Props 12/3.8 CFK, probably switching them later.

AV 200 Photohigher temporarily mounted

since i decided to use the WK-M on my new system gonna build up the thread about it here.

Following frame:

View attachment 836

View attachment 837

View attachment 838

View attachment 839

gonna cnc some carbon plates to mount the MC and IMU, and LED. To stay in the tower format hoping thats gonna give me enough space to mount the ESCs on the center-plate.

View attachment 840

Specs:

Axi 2820/14

Turnigy Plush 40A ESC

Graupner 22 mx with 35MHz Module back in

SCM 16 Graupner.

Props 12/3.8 CFK, probably switching them later.

AV 200 Photohigher temporarily mounted