Pumpkinguy

Member

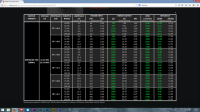

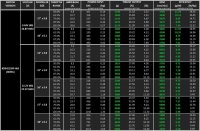

Hey folks. This will be the start of my 1000mm medium lifter.

Specs are as follows:

Gryphon 1000mm Hex frame.

SuperX FC with OSD

KDE 55A Esc's

Kde 4014-380 motors changed to 4215's

Either 2 x 6s 10000's or 16000's in parallel

It will carry a GH-4

First ecalc is based on 2 x 10000 batteries and 17 x 5.8 props

Second is based on 2 x 16000 batteries and 17 x 5.8 props

Third is based on 2 x 16000 batteries and 18 x 6.1 props.

I didn't know what to put for motor cooling so I used good.

As you can see in the last ecalc I am a bit over temp. If I change motor cooling from good to excellent, temps are great. If I change motor cooling to normal temps are high.

please let me know what you think.

Thanks

View attachment 21755 View attachment 21756 View attachment 21757 View attachment 21758

Specs are as follows:

Gryphon 1000mm Hex frame.

SuperX FC with OSD

KDE 55A Esc's

Kde 4014-380 motors changed to 4215's

Either 2 x 6s 10000's or 16000's in parallel

It will carry a GH-4

First ecalc is based on 2 x 10000 batteries and 17 x 5.8 props

Second is based on 2 x 16000 batteries and 17 x 5.8 props

Third is based on 2 x 16000 batteries and 18 x 6.1 props.

I didn't know what to put for motor cooling so I used good.

As you can see in the last ecalc I am a bit over temp. If I change motor cooling from good to excellent, temps are great. If I change motor cooling to normal temps are high.

please let me know what you think.

Thanks

View attachment 21755 View attachment 21756 View attachment 21757 View attachment 21758

Attachments

Last edited by a moderator: