SoCal Blur: Thanks ! I was an engineer, but used machines a lot for prototypes at work and hobby work at home. I didn't have a classical education in machining but it was pretty easy to figure out as I went. Learning the basics comes quickly and once one has the feel of a machine, the rest is really just imagination. I am sure you could pick it up quickly and start creating just about any parts you want.

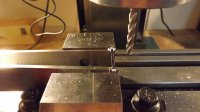

About five years ago I purchased two new hobby machines, a mill and a lathe. I have the Grizzly G4000 lathe and the G6109 mill. With some simple modifications and adjustments, they produce parts that are reasonably accurate (.001" or better is typical). They are not terribly expensive or difficult to work with. They do pay for themselves quickly, depending on frequency of use. Not being industrial machines, there are limitations that require a certain level of patience however. If you have the desire to do it, I highly recommend taking that step. It really does open up new possibilities in the hobby.

The Wraith has options yet to be explored. FPV is top of the list. Retractable landing gear, just for the fun of it. She will be mostly airframe, with limited sections protected with a 'shield' if you will. The overall look planned is that of a mechanical insect. The FPV camera for instance is set up to be the head. It is also why the camera gimbals assembly is more ornate than need be. I want to be able to look past the shielding and see the cool mechanisms beneath. I am also contemplating designing a miniature BB gun for it. It would be fun to shoot targets like cans, etc. I don't expect extreme efficiency, after all this is all about fun. But, everything that is going into her is designed to be as efficient as possible to make up for the toys.

About five years ago I purchased two new hobby machines, a mill and a lathe. I have the Grizzly G4000 lathe and the G6109 mill. With some simple modifications and adjustments, they produce parts that are reasonably accurate (.001" or better is typical). They are not terribly expensive or difficult to work with. They do pay for themselves quickly, depending on frequency of use. Not being industrial machines, there are limitations that require a certain level of patience however. If you have the desire to do it, I highly recommend taking that step. It really does open up new possibilities in the hobby.

The Wraith has options yet to be explored. FPV is top of the list. Retractable landing gear, just for the fun of it. She will be mostly airframe, with limited sections protected with a 'shield' if you will. The overall look planned is that of a mechanical insect. The FPV camera for instance is set up to be the head. It is also why the camera gimbals assembly is more ornate than need be. I want to be able to look past the shielding and see the cool mechanisms beneath. I am also contemplating designing a miniature BB gun for it. It would be fun to shoot targets like cans, etc. I don't expect extreme efficiency, after all this is all about fun. But, everything that is going into her is designed to be as efficient as possible to make up for the toys.

Last edited by a moderator: