Hexacrafter

Manufacturer

Most never need to make any adjustments to motor alignment as they are usually within .1 degree. The very large frames can be a bit more..

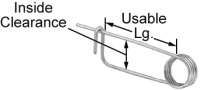

For those seeking perfection, adjustments can be made by either sanding the arm as done by Kloner or by using shim washers under one side of the motor. Usually 1 shim on the 2 low side motor bolts works perfect.

We have started shipping motor shim washers with the kits to make it as easy as possible.

They are nothing special created by HexaCrafter, but rather standard 3mm x 6mm x 0.1mm steel washer shims.

The process takes a few minutes per motor, but once it is done, it is permanent and further tuning is not required.

For those seeking perfection, adjustments can be made by either sanding the arm as done by Kloner or by using shim washers under one side of the motor. Usually 1 shim on the 2 low side motor bolts works perfect.

We have started shipping motor shim washers with the kits to make it as easy as possible.

They are nothing special created by HexaCrafter, but rather standard 3mm x 6mm x 0.1mm steel washer shims.

The process takes a few minutes per motor, but once it is done, it is permanent and further tuning is not required.