You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Take care with the new 2.3 software for A2 Today i crashed my Evo 800 S with Z15

- Thread starter crowjet

- Start date

BirdsEyeProd

Member

This will turn into another "Not our fault" thread.

Good luck with everything crowjet. I just had my A2 equipped copter go in and I KNOW it wasn't an ESC error like they are saying.

Good luck with everything crowjet. I just had my A2 equipped copter go in and I KNOW it wasn't an ESC error like they are saying.

gtranquilla

RadioActive

From what I recall the answer seems to be yes....

I know I have asked this on another thread but still looking for a definitive answer, in the light of all these A2 disasters I am going to replace the A2 on my S1000 but want to know can I use the A2 IMU?

Anyone? Dji support?

Cheers

fdproductions

FD Productions

jean,

im so sad to see this picture and i am very sorry this happened. for future reference if your going to be flying the s800 evo again, just please make sure you get in the habit of replacing those rubber gromments every twenty flights and take note of how the motors have a ****-eyed orientation to them every alternate motor sits either left or right from whatever I could see in your pictures m4-cw-left side-short side of grommet high - top of screw which is correct but if you go to your illustration and notice your M1 it looks like the left side is also top but I could be mistaken since the arms are connected but sure seems like m1 is tilted in the wrong direction (since this is an odd number.)

Also I know the a2 imu doesn't need to be mounted on the imu plate but also it shouldn't be mounted to close to the edge of the frame by the arrow (this could also be result of crash) one last thing I love how clean your set up is but with the A2 if your CAN1 and CAN2's aren't shoegooed on or if not shoegooed visibly present your asking for major catastrophe.

hope that was helpful so glad that lens survived :0).

im so sad to see this picture and i am very sorry this happened. for future reference if your going to be flying the s800 evo again, just please make sure you get in the habit of replacing those rubber gromments every twenty flights and take note of how the motors have a ****-eyed orientation to them every alternate motor sits either left or right from whatever I could see in your pictures m4-cw-left side-short side of grommet high - top of screw which is correct but if you go to your illustration and notice your M1 it looks like the left side is also top but I could be mistaken since the arms are connected but sure seems like m1 is tilted in the wrong direction (since this is an odd number.)

Also I know the a2 imu doesn't need to be mounted on the imu plate but also it shouldn't be mounted to close to the edge of the frame by the arrow (this could also be result of crash) one last thing I love how clean your set up is but with the A2 if your CAN1 and CAN2's aren't shoegooed on or if not shoegooed visibly present your asking for major catastrophe.

hope that was helpful so glad that lens survived :0).

HI EVERYBODY:

For these accidents or faults or firmware or hardware the only solution I see is to have a parachute system like Opale for S800 or similar to 8 kilos weight.

Not 100% sure they always display properly because it depends on the position of the S800 or the like, but I think 90% would be an accurate figure.

At least avoid total losses unless they fall on a highway in traffic or in the water ....

I have it, I've never used but if it had been a year ago would have prevented losing a complete S800 bacause i have battery failure.

You can shoot from the RC or the F2 Wookong, i dont not know if you can from A2 ....

Not is a expensive system, as 700 euros, but there's more economic systems, we think that several thousand flying i do not think 700 is expensive ...

regards

For these accidents or faults or firmware or hardware the only solution I see is to have a parachute system like Opale for S800 or similar to 8 kilos weight.

Not 100% sure they always display properly because it depends on the position of the S800 or the like, but I think 90% would be an accurate figure.

At least avoid total losses unless they fall on a highway in traffic or in the water ....

I have it, I've never used but if it had been a year ago would have prevented losing a complete S800 bacause i have battery failure.

You can shoot from the RC or the F2 Wookong, i dont not know if you can from A2 ....

Not is a expensive system, as 700 euros, but there's more economic systems, we think that several thousand flying i do not think 700 is expensive ...

regards

roryhinds

Member

a parachute needs time to open and on most film production shoots you don't fly high enough to get any use out of a parachute. Low altitude flying is what the multi-rotor is all about and getting that amazing shot.

Besides these parachutes still have the craft descending at a high speed enough to do damage to a Red camera so my thinking is the parachute systems are nice in theory but useless in the real world.

Besides these parachutes still have the craft descending at a high speed enough to do damage to a Red camera so my thinking is the parachute systems are nice in theory but useless in the real world.

a parachute needs time to open and on most film production shoots you don't fly high enough to get any use out of a parachute. Low altitude flying is what the multi-rotor is all about and getting that amazing shot.

Besides these parachutes still have the craft descending at a high speed enough to do damage to a Red camera so my thinking is the parachute systems are nice in theory but useless in the real world.

Roryhinds.

You are wrong...please see this and look the videos

http://www.opale-paramodels.com/ind...ms/rescue-kit/rescue-kit-for-dji-s1000-detail

roryhinds

Member

Would love to be wrong. Show me this working at a lower attitude with a camera payload. And show me this working with a Coaxial setup.

Having a parachute system that worked would be amazing but the reality of it it doesn't when you have a payload on and are flying low altitude which is what film productions require.

Having a parachute system that worked would be amazing but the reality of it it doesn't when you have a payload on and are flying low altitude which is what film productions require.

roryhinds

Member

jean,

im so sad to see this picture and i am very sorry this happened. for future reference if your going to be flying the s800 evo again, just please make sure you get in the habit of replacing those rubber gromments every twenty flights and take note of how the motors have a ****-eyed orientation to them every alternate motor sits either left or right from whatever I could see in your pictures m4-cw-left side-short side of grommet high - top of screw which is correct but if you go to your illustration and notice your M1 it looks like the left side is also top but I could be mistaken since the arms are connected but sure seems like m1 is tilted in the wrong direction (since this is an odd number.)

Also I know the a2 imu doesn't need to be mounted on the imu plate but also it shouldn't be mounted to close to the edge of the frame by the arrow (this could also be result of crash) one last thing I love how clean your set up is but with the A2 if your CAN1 and CAN2's aren't shoegooed on or if not shoegooed visibly present your asking for major catastrophe.

hope that was helpful so glad that lens survived :0).

The A2's that I've used have the Can1 & Can2 so tight and secure from the pressure of the ESC's plugged in that it pushes everything super tight. I actually have to use pliers to take the ESC's out first before it loosens up enough to take the Can1 & Can2 cables out.

What is with the shoe goo-ing?

fdproductions

FD Productions

rory im not sure i have any idea what your talking about but im certain its not the same components, theres only two non servo wires going into the A2 FC the two grey connectors have no clip and are very flexible and filmsy and susceptible to loosing midflight without glueing the outside permitter of the connector to secure information flowing in and out of FC.

The A2's that I've used have the Can1 & Can2 so tight and secure from the pressure of the ESC's plugged in that it pushes everything super tight. I actually have to use pliers to take the ESC's out first before it loosens up enough to take the Can1 & Can2 cables out.

What is with the shoe goo-ing?

fdproductions

FD Productions

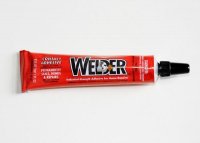

shoe gooing refers to the use of utilizing a very strong holding glue that removes easily and is made for glueing the soles of shoes back together: http://www.amazon.com/Shoe-GOO®-Adhesive-Black-3-7/dp/B004PBOJE8

vertically hanging A2 components almost guarantees the eventual loosening of the connections because of all the air is coming from the aircraft moving forward in flight, im not sure how else to explain this.The A2's that I've used have the Can1 & Can2 so tight and secure from the pressure of the ESC's plugged in that it pushes everything super tight. I actually have to use pliers to take the ESC's out first before it loosens up enough to take the Can1 & Can2 cables out.

What is with the shoe goo-ing?

gtranquilla

RadioActive

The esc servo connectors tend to be a tight fit on the A2 the first few times..... adjacent are two gray canbus type connectors and another one or two that are connected to others components such as the iOSD...... these tend to be less than a snug fit and are just as critical for safe flight.

UAVProducts has been using hotglue gun glue as do I to hold these on better. I prefer the hot glue method because the glue is typically easier to remove and does not contain any harsh, eroding or corrosive chemicals. Some silicone and other glues can cause copper to oxidize and that is not good at all!

There is a lot of data passing thru a canbus as well as an s.bus connection.... so if there is a loose connection, all that data fails to transfer or data corruption occurs.

UAVProducts has been using hotglue gun glue as do I to hold these on better. I prefer the hot glue method because the glue is typically easier to remove and does not contain any harsh, eroding or corrosive chemicals. Some silicone and other glues can cause copper to oxidize and that is not good at all!

There is a lot of data passing thru a canbus as well as an s.bus connection.... so if there is a loose connection, all that data fails to transfer or data corruption occurs.

fdproductions

FD Productions

The esc servo connectors tend to be a tight fit on the A2 the first few times..... adjacent are two gray canbus type connectors and another one or two that are connected to others components such as the iOSD...... these tend to be less than a snug fit and are just as critical for safe flight.

UAVProducts has been using hotglue gun glue as do I to hold these on better. I prefer the hot glue method because the glue is typically easier to remove and does not contain any harsh, eroding or corrosive chemicals. Some silicone and other glues can cause copper to oxidize and that is not good at all!

There is a lot of data passing thru a canbus as well as an s.bus connection.... so if there is a loose connection, all that data fails to transfer or data corruption occurs.

Thank you Tranquilla, sorry if I wasn't clear in prior posts. You said it best.

fdproductions

FD Productions

is it black? looks solid may have to start using this stuff now

PeterLester

Member

I must try that! Thanks Kloner.

Welders adhesive is the prefered liquid to use, pull one end and it pops right off, non corrosive

I am a little confused. If this is suppose to be a great adhesive how are you able to pop it right off if you need to unplug the canibus connector?

Andy