shortsonfire79

Member

Hey guys!

I had been toying with the idea of building myself a multicopter, but I was pretty hesitant about it because I had little knowledge of what I was doing and I'm broke. But as a thanks from my sister for some wedding junk, she bought me a GoPro and a Bumblebee quadcopter! I have no idea of what I'm doing with it, and I posted to r/multicopter and the guys there gave me some solid info, but I'm much more comfortable with the forum setting than I am with Reddit. They pointed me in a direction of what kind of things to buy, as the set wasn't quite complete (my sis didn't know what she was doing either, she had to ask friends for help) so I'll post some pictures, as they speak more than my little knowledge.

Stuff in the box:

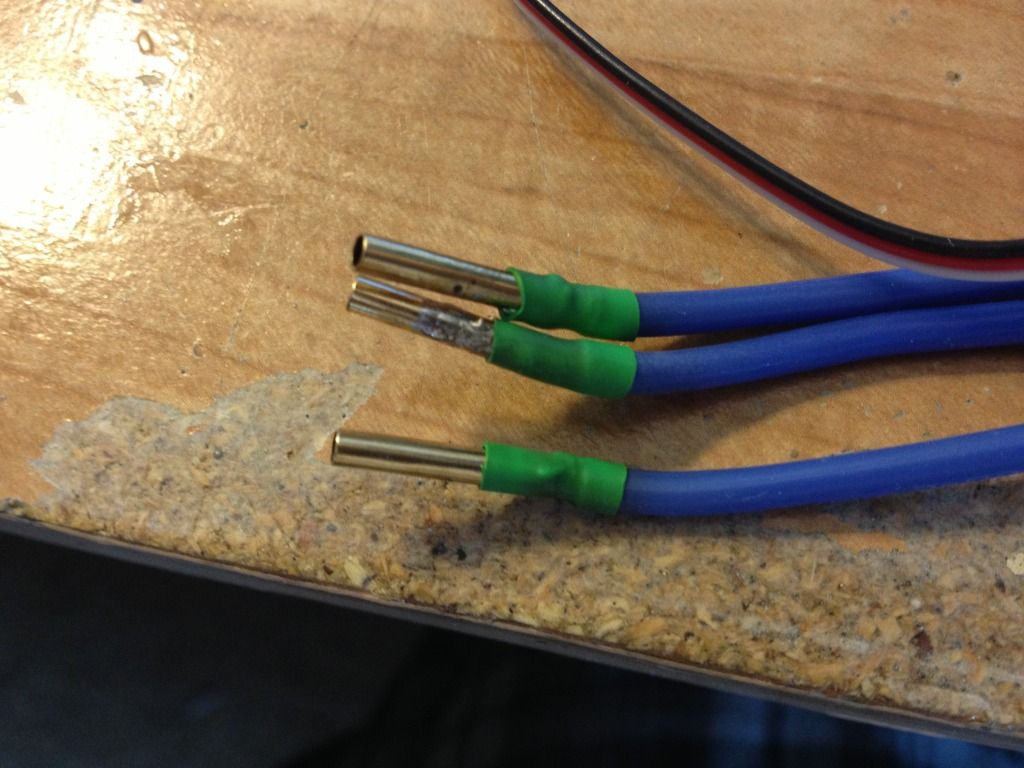

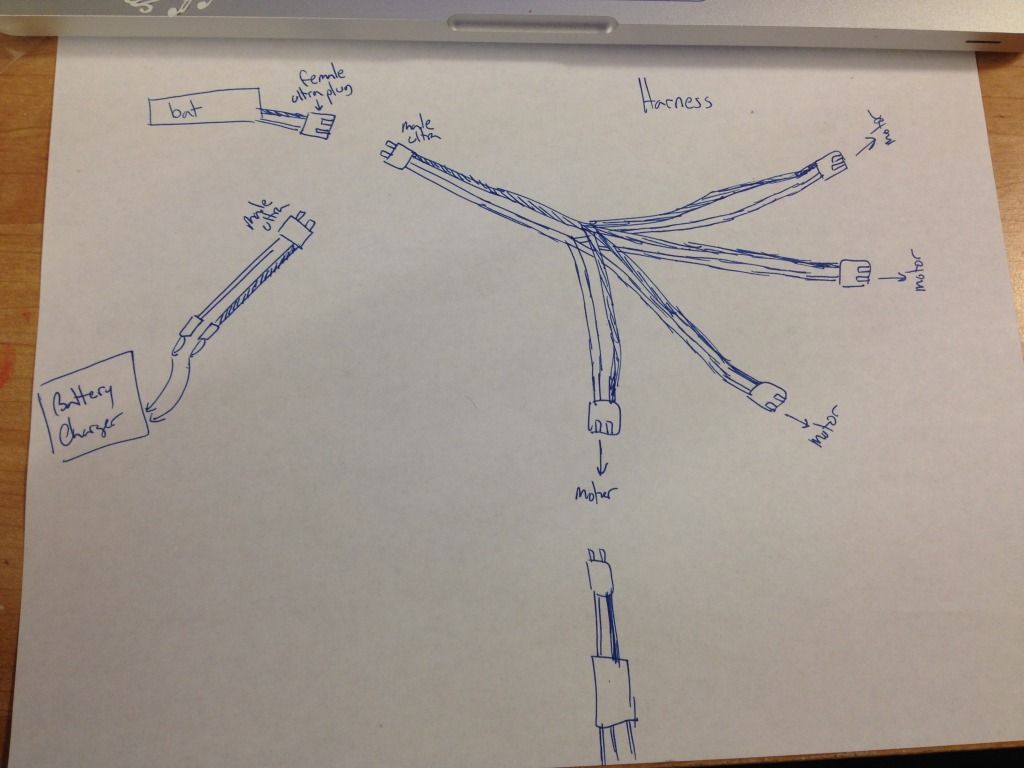

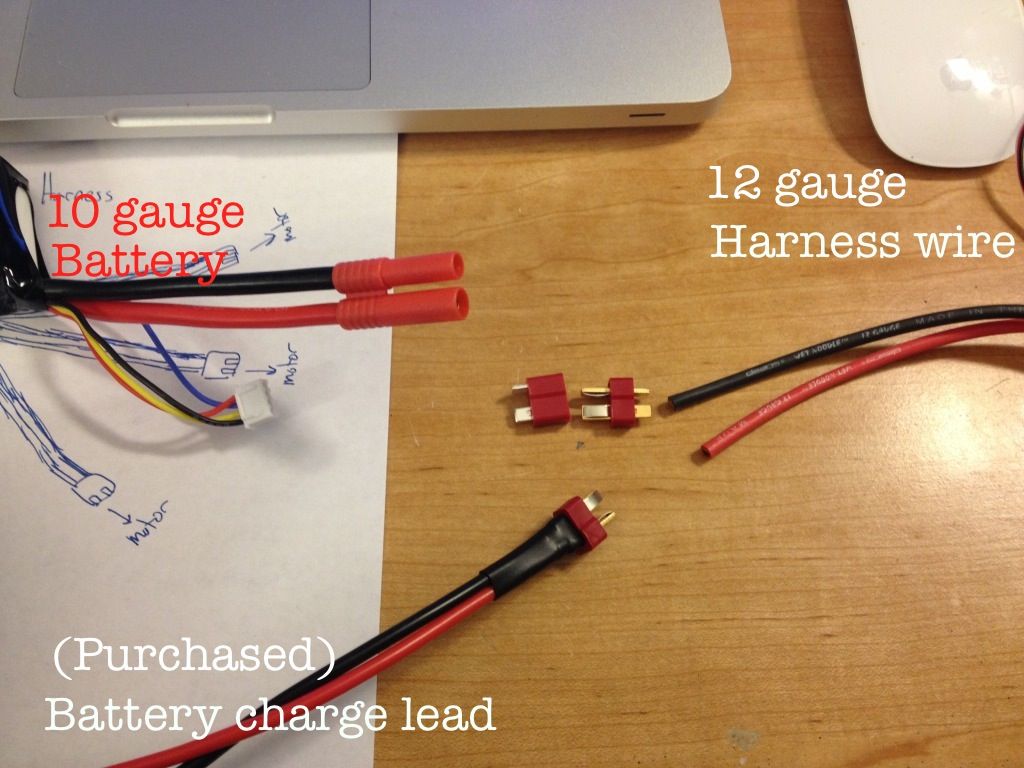

Since I was down at uni, I didn't know of the best place to get the missing connectors and such, so I sat on this guy for a month until I was able to get home and hit the hobby store yesterday. I brought the instruction manual I found online and the box and just asked "what do I do? They said I need bullet connectors and a four way wire harness?" The guy was able to hook me up with 3 bullet connectors, but they were out of stock for the rest. He also provided me with a battery charger and some other bits like Ultra Plugs...which I have no idea of what they do...

Here's a pic!

I am so terribly lost. Here's the instruction manual, if it'll help you help me... I'm a broke uni student getting ready for the holiday expenses, so hopefully there aren't many more things I need to buy. I know for certain that I need another few sets of bullet connectors and that power harness, but is there anything else? And my soldering skills are quite poor; I soldered some board for my underwater ROV and...it failed. (might have gotten wet, which wasn't my fault. ) I've watched this video quite a few times, but I can't really figure out whats what. Not sure why, the video is so straight forward... Any help you'd be able to provide would be greatly appreciated! :livid: I'll be in town until Friday, so if I need to buy more stuff that I can't find online, I have a bit of time.

) I've watched this video quite a few times, but I can't really figure out whats what. Not sure why, the video is so straight forward... Any help you'd be able to provide would be greatly appreciated! :livid: I'll be in town until Friday, so if I need to buy more stuff that I can't find online, I have a bit of time.

Tldr: I'm an idiot with a built it yourself quadcopter. Where to I start and what else do I need to buy?

Thanks a bunch!!

I had been toying with the idea of building myself a multicopter, but I was pretty hesitant about it because I had little knowledge of what I was doing and I'm broke. But as a thanks from my sister for some wedding junk, she bought me a GoPro and a Bumblebee quadcopter! I have no idea of what I'm doing with it, and I posted to r/multicopter and the guys there gave me some solid info, but I'm much more comfortable with the forum setting than I am with Reddit. They pointed me in a direction of what kind of things to buy, as the set wasn't quite complete (my sis didn't know what she was doing either, she had to ask friends for help) so I'll post some pictures, as they speak more than my little knowledge.

Stuff in the box:

Since I was down at uni, I didn't know of the best place to get the missing connectors and such, so I sat on this guy for a month until I was able to get home and hit the hobby store yesterday. I brought the instruction manual I found online and the box and just asked "what do I do? They said I need bullet connectors and a four way wire harness?" The guy was able to hook me up with 3 bullet connectors, but they were out of stock for the rest. He also provided me with a battery charger and some other bits like Ultra Plugs...which I have no idea of what they do...

Here's a pic!

I am so terribly lost. Here's the instruction manual, if it'll help you help me... I'm a broke uni student getting ready for the holiday expenses, so hopefully there aren't many more things I need to buy. I know for certain that I need another few sets of bullet connectors and that power harness, but is there anything else? And my soldering skills are quite poor; I soldered some board for my underwater ROV and...it failed. (might have gotten wet, which wasn't my fault.

Tldr: I'm an idiot with a built it yourself quadcopter. Where to I start and what else do I need to buy?

Thanks a bunch!!