Droider

Drone Enthusiast

Pucker work and thanks for sharing. I did whiteness a maiden of a S1000 the other day, I can't believe those soft plastic props could possibly be so efficient.

They look and feel totally naff and way to flexible for my liking but your tests proof me wrong.. I would have thought they have to be safer than a ridged prop, maybe something could be used to see what damage is inflicted by both props a full throttle, I am guessing the ridged has to do more damage.

GREAT REVEIW.

Dave

They look and feel totally naff and way to flexible for my liking but your tests proof me wrong.. I would have thought they have to be safer than a ridged prop, maybe something could be used to see what damage is inflicted by both props a full throttle, I am guessing the ridged has to do more damage.

GREAT REVEIW.

Dave

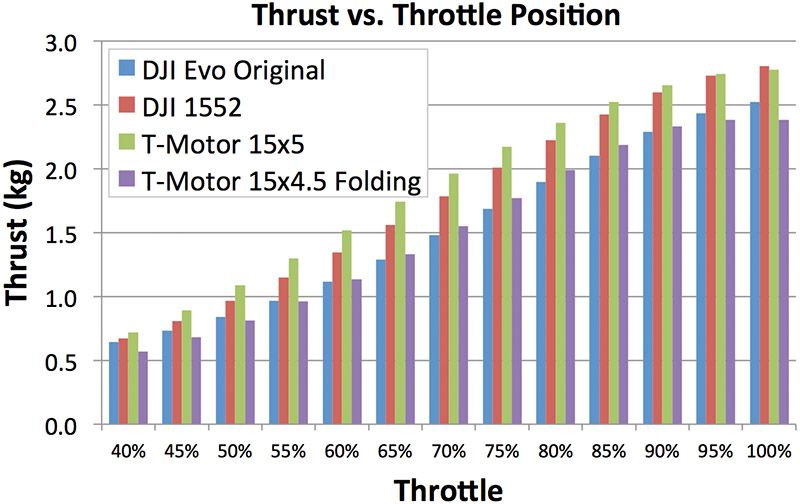

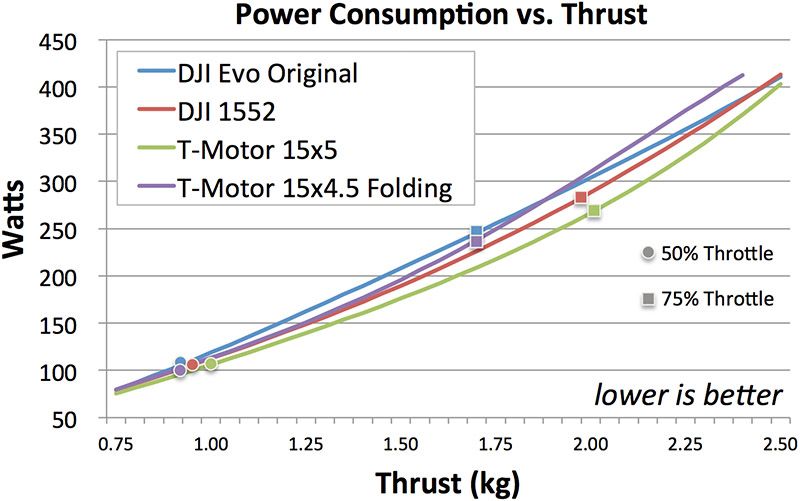

Here is an update that includes the recently released T-Motor 15-inch folding prop. These new props come with mounting brackets that are the same dimensions as used by DJI's folding props, and mount easily to the S800 Evo and S1000 motors, as well as to T-Motor's own compatible motors.

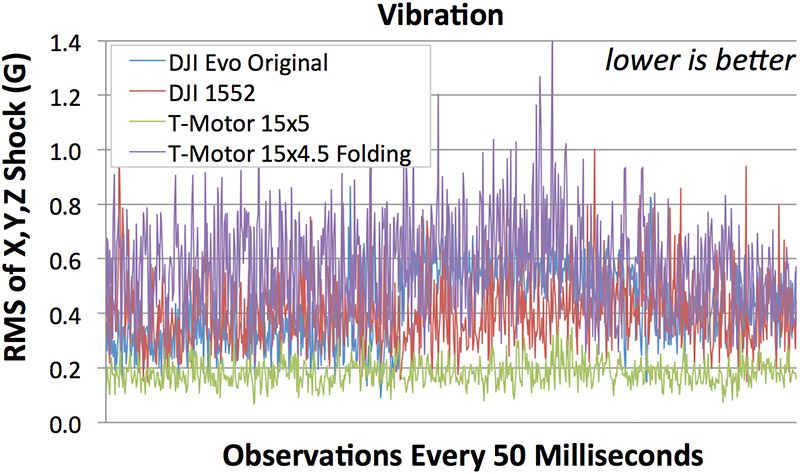

In sum, the T-Motor folder is inferior to DJI's 1552 folding design. It is no better at low throttle settings and substantially worse at higher throttle. The T-Motor folder is comparable to the original DJI Evo prop in both appearance and function. It is a better than the original Evo prop at lower throttle and worse at higher throttle. As with DJI's folders, the T-Motor folding prop's vibration characteristics are markedly inferior to a one-piece design.

Flyers using 15-inch props and who desire a folding design should stick with DJI's 1552s on the S800 Evo and S1000 platforms. On other platforms, the T-Motor folders are fine props, but not up to the standard set by DJI with its 1552 design. Like all folders measured here, the new T-Motor folders are inferior to T-Motor's very impressive one-piece carbon fiber prop.

Updated photo/charts follow: