Bartman

Welcome to MultiRotorForums.com!!

Hi everyone,

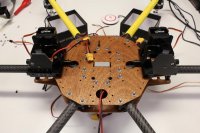

I've been working on a new build for the last few weeks and decided I'd do a build thread to show what I've been up to. It's a bit unique in some ways and pretty typical in others. This first video is how I start a build. Some people go to ecalc, I do a quick tally of what I'm planning to do and then consult performance charts to see if I'm in the ballpark weight and lift wise.

The build is actually pretty far along and I've got a bunch of photos that I'll post later this evening.

Keep in mind, the process shown in the video is iterative, you start with the best guess you can come up with for each line and then see how it looks when done. If it's very far off then you modify your selections to try to bring it into line with your goals. In this case the camera, camera mount, flight control system, and motors were pretty well set in stone. If the calculation was very far off then I'd have to maybe consider adding two motor motors, maybe smaller batteries, or something else that would improve the resulting outcome. Even though the video is sort of played like it's a first run of the numbers I had actually checked everything before getting started with the build so the numbers worked out ok in the video. I really did decide at that moment to reduce the arm lengths for 15" props instead of 16" props which would have been unnecessarily long for larger dia. props I would have never used.

Thanks!

Bart

I've been working on a new build for the last few weeks and decided I'd do a build thread to show what I've been up to. It's a bit unique in some ways and pretty typical in others. This first video is how I start a build. Some people go to ecalc, I do a quick tally of what I'm planning to do and then consult performance charts to see if I'm in the ballpark weight and lift wise.

The build is actually pretty far along and I've got a bunch of photos that I'll post later this evening.

Keep in mind, the process shown in the video is iterative, you start with the best guess you can come up with for each line and then see how it looks when done. If it's very far off then you modify your selections to try to bring it into line with your goals. In this case the camera, camera mount, flight control system, and motors were pretty well set in stone. If the calculation was very far off then I'd have to maybe consider adding two motor motors, maybe smaller batteries, or something else that would improve the resulting outcome. Even though the video is sort of played like it's a first run of the numbers I had actually checked everything before getting started with the build so the numbers worked out ok in the video. I really did decide at that moment to reduce the arm lengths for 15" props instead of 16" props which would have been unnecessarily long for larger dia. props I would have never used.

Thanks!

Bart

Last edited by a moderator: