jfro

Aerial Fun

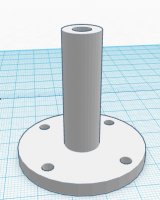

I'm trying an experiment and trying to make this part for a yaw shaft. Shaft is 12mm with a 6mm bore leaving 3mm walls which is within 3d specs for printing in Stainless which they claim is very strong.

Look for help on 2-3 fronts.

Is stainless 3d printing going to be strong enough to hang 6-8 lbs?

If I buy 12mm ID flanged bearings, does the shaft get made at 12MM or something less?

Is 2-3 weeks normal for something like this in 3d printing. This will be my first attempt.

Thanks in advance for any help or suggestions.

Look for help on 2-3 fronts.

Is stainless 3d printing going to be strong enough to hang 6-8 lbs?

If I buy 12mm ID flanged bearings, does the shaft get made at 12MM or something less?

Is 2-3 weeks normal for something like this in 3d printing. This will be my first attempt.

Thanks in advance for any help or suggestions.