AEA737

Member

Hello everyone.

I took my hexa with me to film while on vacation. I flew a lot, very happy for bringing it for early morning and evening flights.

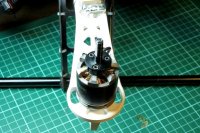

While assembling the props back one of them just fell on my hand as the three M2 hex bolts that told the shaft of the motors where broken.

I decided to take a look at the rest of the motors and only two had the three bolts intact! Some of them where only holding the shaft only by one bolt.

The problem now is to remove the broken part of the bolt that´s inside the motor. How can I do that? Is it better to send them somewhere to be serviced?

Thanks,

Javier

View attachment 13617View attachment 13618View attachment 13619View attachment 13620View attachment 13621

I took my hexa with me to film while on vacation. I flew a lot, very happy for bringing it for early morning and evening flights.

While assembling the props back one of them just fell on my hand as the three M2 hex bolts that told the shaft of the motors where broken.

I decided to take a look at the rest of the motors and only two had the three bolts intact! Some of them where only holding the shaft only by one bolt.

The problem now is to remove the broken part of the bolt that´s inside the motor. How can I do that? Is it better to send them somewhere to be serviced?

Thanks,

Javier

View attachment 13617View attachment 13618View attachment 13619View attachment 13620View attachment 13621