Bartman

Welcome to MultiRotorForums.com!!

For the last four or five weeks I've been trying to spend some time fiddling with my camera mount. It takes great pictures but was pretty terrible at taking video. Reading through DennyR's many posts made me think a lot about what I'd have to do to get my equipment working better. I started by just sitting it on my bench and prodding it to see where all the movement was coming from. In doing this I also started to formulate some theories about what would make the mount better.

The first thing I realized is that if something like a flight control is providing stabilization then everything not being actively controlled shouldn't move. You can't have five different components free to move in five different ways all in the name of vibration isolation if none of them are being controlled by something. Anything that isn't being controlled therefore has to be constrained.

The first mod was therefore to remove the greatest amount of unconstrained movement I could find which was in the mounts. They were very flimsy carbon fiber plates and they would flex at least 3/8" when I lifted the copter before the mount would lift off the ground. This allowed the mount to swing like a bull whip every time the momentum of the mount slowed or shifted. Here's a pic of the new mounting plates which have zero give when the whole heli is lifted off the ground.

View attachment 506View attachment 510

You can also see in that picture that I put nylon bolts through the orange squishy rubber pieces. The squishy orange pieces support the weight of the mount and also provide a pretty effective vibration barrier but with the weight of the mount as I've got it set up, they are sometimes left trying to pull the mount back in place and they're just not meant to do that. In wind they would often pull out of their mounting holes and cause wires to disconnect. The solution was to constrain them with nylon bolts so they only act to support the weight in compression and the bolts keep the mount from having a range of motion that isn't being stabilized by the FC.

The next largest unconstrained movement came from the four rubber grommets where the mount's bars passed through the mount's frame. These grommets were plain black rubber inserted into holes in thin carbon fiber plate. There was virtually no bearing surface for the grommets to push against so the carbon fiber would just dig into the rubber leaving the mount with another direction to swing when I slowed down, sped up, or changed direction. To fix it I added 3/32 plywood rings and drilled them large enough so I could put latex tubing over the bars and have them fit snugly into the holes. It still leaves me with some protection from vibration but there is virtually no movement so the camera is much more stable.

View attachment 507View attachment 508

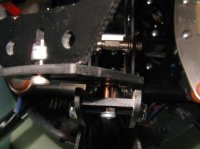

Specific to the MKTR mount is a pivot point where a small 4mm bolt sticks through some carbon plate and spans a gap before capturing the camera sling. There's no bearing or anything constraining the bolt so the mount was very sloppy and inconsistent when pivoting on that point. I was lucky that a motor bearing fit right in and two small washers kept it from binding on the plate. Now the mount pivots smoothly and the camera is more stable in pitch.

View attachment 509

I guess the moral of all this is that don't just assume the mount you've purchased is as good as it gets. Take a close look at it and don't accept sloppy performance from individual components that don't quite do what the designer intended.

Movement in the mount is bad. If it's specifically being controlled by a stabilization system then that's fine; tune it, lube it, do whatever it takes to make the control function smoothly. If the movement though isn't being controlled then it has to be constrained. If you can introduce some vibration isolation material in there that's fine but don't accept unconstrained or uncontrolled movement in the name of vibration isolation. I guess that's the point of all this. Don't let your mount swing and shake and make the stabilization system's job even harder in the name of vibration isolation.

Any further input would be appreciated.

What's interesting is that when you remove these big sources of free movement within your mount, smaller sources of shake or jitter become more obvious but they're not as easy to fix. It's a challenge but the end result is extremely worth it.

Hope that helps,

Bart

The first thing I realized is that if something like a flight control is providing stabilization then everything not being actively controlled shouldn't move. You can't have five different components free to move in five different ways all in the name of vibration isolation if none of them are being controlled by something. Anything that isn't being controlled therefore has to be constrained.

The first mod was therefore to remove the greatest amount of unconstrained movement I could find which was in the mounts. They were very flimsy carbon fiber plates and they would flex at least 3/8" when I lifted the copter before the mount would lift off the ground. This allowed the mount to swing like a bull whip every time the momentum of the mount slowed or shifted. Here's a pic of the new mounting plates which have zero give when the whole heli is lifted off the ground.

View attachment 506View attachment 510

You can also see in that picture that I put nylon bolts through the orange squishy rubber pieces. The squishy orange pieces support the weight of the mount and also provide a pretty effective vibration barrier but with the weight of the mount as I've got it set up, they are sometimes left trying to pull the mount back in place and they're just not meant to do that. In wind they would often pull out of their mounting holes and cause wires to disconnect. The solution was to constrain them with nylon bolts so they only act to support the weight in compression and the bolts keep the mount from having a range of motion that isn't being stabilized by the FC.

The next largest unconstrained movement came from the four rubber grommets where the mount's bars passed through the mount's frame. These grommets were plain black rubber inserted into holes in thin carbon fiber plate. There was virtually no bearing surface for the grommets to push against so the carbon fiber would just dig into the rubber leaving the mount with another direction to swing when I slowed down, sped up, or changed direction. To fix it I added 3/32 plywood rings and drilled them large enough so I could put latex tubing over the bars and have them fit snugly into the holes. It still leaves me with some protection from vibration but there is virtually no movement so the camera is much more stable.

View attachment 507View attachment 508

Specific to the MKTR mount is a pivot point where a small 4mm bolt sticks through some carbon plate and spans a gap before capturing the camera sling. There's no bearing or anything constraining the bolt so the mount was very sloppy and inconsistent when pivoting on that point. I was lucky that a motor bearing fit right in and two small washers kept it from binding on the plate. Now the mount pivots smoothly and the camera is more stable in pitch.

View attachment 509

I guess the moral of all this is that don't just assume the mount you've purchased is as good as it gets. Take a close look at it and don't accept sloppy performance from individual components that don't quite do what the designer intended.

Movement in the mount is bad. If it's specifically being controlled by a stabilization system then that's fine; tune it, lube it, do whatever it takes to make the control function smoothly. If the movement though isn't being controlled then it has to be constrained. If you can introduce some vibration isolation material in there that's fine but don't accept unconstrained or uncontrolled movement in the name of vibration isolation. I guess that's the point of all this. Don't let your mount swing and shake and make the stabilization system's job even harder in the name of vibration isolation.

Any further input would be appreciated.

What's interesting is that when you remove these big sources of free movement within your mount, smaller sources of shake or jitter become more obvious but they're not as easy to fix. It's a challenge but the end result is extremely worth it.

Hope that helps,

Bart