Easy to find new bearings. The existing bearings should have a number on stamped on them. Otherwise just measure outside diameter, inside diameter and thickness (e.g. 11mm x 4mm x 5mm). Call SMB Bearings (http://www.smbbearings.com/) - you'll get straightforward advice and fast service.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

AnakA System

- Thread starter anaka

- Start date

Disassemble the motor then try just pushing the bearings out using gentle pressure against the shaft. If that doesn't work, or the shaft comes out leaving the bearings in place, place the motor in a warm oven - about 80-90ºC for about ten minutes - that should soften any glue they might have used and also expand the bore a little so the bearings should then either drop out or be easy to push out. Insert the new bearings while the casing is still hot - if they are a tight fit then use gentle pressure in a vice or with a G-clamp - never hammer them! If there was glue present then what is left should be enough to hold the new bearing. Otherwise use Loctite 641.

I'd recommend you also get a supply of new circlips and shim washers (if there's one under the circlip) - http://www.calebcomp.co.uk/index.html - use new ones every time.

I'd recommend you also get a supply of new circlips and shim washers (if there's one under the circlip) - http://www.calebcomp.co.uk/index.html - use new ones every time.

anaka

Member

latest approach to vibrations reduction

View attachment 4967View attachment 4968View attachment 4969

I bought gel cubes from RS and gave one more chance to my previous dampening system, these new gel cubes are softer than the ones I had before, also than the 2 kind of foams

respect to the old dumpers setting I added one more cube between dumpers and main frame, this gives even more stability

with my square tube arms and my motors, that are going to need new ballbearings and produce a good quantyty of vibrations the results are very good

I think I found the definitive solution so now can focus on other fixes

View attachment 4967View attachment 4968View attachment 4969

I bought gel cubes from RS and gave one more chance to my previous dampening system, these new gel cubes are softer than the ones I had before, also than the 2 kind of foams

respect to the old dumpers setting I added one more cube between dumpers and main frame, this gives even more stability

with my square tube arms and my motors, that are going to need new ballbearings and produce a good quantyty of vibrations the results are very good

I think I found the definitive solution so now can focus on other fixes

Attachments

Last edited by a moderator:

anaka

Member

View attachment 5101View attachment 5102View attachment 5103View attachment 5104

after several tests with the new frame I decided to switch back to the previous one, a bit more heavy but much more rigid and stable, rectangular tubes behave very well for vibrations

I made a quick test with 12x4" propellers, rinning motors fast, at the end of the play the results wasn't so exciting and the hardware was overstressed so I mvoed back to APC 13x6.5

after several tests with the new frame I decided to switch back to the previous one, a bit more heavy but much more rigid and stable, rectangular tubes behave very well for vibrations

I made a quick test with 12x4" propellers, rinning motors fast, at the end of the play the results wasn't so exciting and the hardware was overstressed so I mvoed back to APC 13x6.5

Attachments

Last edited by a moderator:

ksrimoungchanh

Member

It rock!.. sure performs like the pros.. what is the investment in materials? I know there is no way to put $$ on time/knowledge.

anaka

Member

honestly I can't say how much money I spent till now..

I can say that the actual frame, made of carbon fiber and other materials with CNC milling and tube clamps, it costs to me around 350€ then you can add the costs for electronics and camera gimbal and you have an idea of the possible RTF cost

the pictures in the posts above are not the actual frame for that quality the costs are around 100€

soon will post some new pictures that show wich materials and cnc machinery I made for the actual configuration and price

I can say that the actual frame, made of carbon fiber and other materials with CNC milling and tube clamps, it costs to me around 350€ then you can add the costs for electronics and camera gimbal and you have an idea of the possible RTF cost

the pictures in the posts above are not the actual frame for that quality the costs are around 100€

soon will post some new pictures that show wich materials and cnc machinery I made for the actual configuration and price

anaka

Member

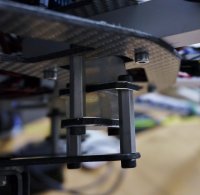

View attachment 7347View attachment 7348View attachment 7349View attachment 7350View attachment 7351

this is the latest build, carbon fiber tubes, legs and motor mounts, PVC clamps, composite material for the central frame

aestetically better, hidden wires, less influence on compass, some grams lighter than before, same stability

this is the latest build, carbon fiber tubes, legs and motor mounts, PVC clamps, composite material for the central frame

aestetically better, hidden wires, less influence on compass, some grams lighter than before, same stability

Attachments

Last edited by a moderator:

anaka

Member

View attachment 7831View attachment 7825View attachment 7828View attachment 7830View attachment 7829

my new custom camera gimbal, as you can see the direct drive is still there

there are several models of camera gimbals on the market, my efforts are on make it as much comfigurable as possible

this new model lets me tune it in all the ways achieving a perfect balance of weights both for the bimbal itself and the camera

I implemented the new Hitech HS 7940 TH ultra fast and strong servos

I also improved the anti vibration system, I balanced the props and changed landing gears configuration so now I can use them to hold batteries

there are no more vibrations of any kind, the total weight with a GH2 and 2 GensAce boxed 5000 mhA is 5,3 Kg and I have around 14 minutes of flight, motors are cold and powerboards warm but it is just a bit...i can touch them with my finger without to burn

my new custom camera gimbal, as you can see the direct drive is still there

there are several models of camera gimbals on the market, my efforts are on make it as much comfigurable as possible

this new model lets me tune it in all the ways achieving a perfect balance of weights both for the bimbal itself and the camera

I implemented the new Hitech HS 7940 TH ultra fast and strong servos

I also improved the anti vibration system, I balanced the props and changed landing gears configuration so now I can use them to hold batteries

there are no more vibrations of any kind, the total weight with a GH2 and 2 GensAce boxed 5000 mhA is 5,3 Kg and I have around 14 minutes of flight, motors are cold and powerboards warm but it is just a bit...i can touch them with my finger without to burn

Attachments

Last edited by a moderator:

anaka

Member

stability in windy conditions, that day it was 10mph strong wind and I was at 5-6m from ground hovering in manual mode

you can notice that no more vibrations of any king are present, no more jello or any motor effect in camera

the wind makes the arms come into the screen often

considering the weather conditions, the custom AV130 with direct drive, standard mikrokopter fc 2.1 stabilization

the quality is reasonably good

I show both the raw data and the post stabilized so you can valuate the effective stability of the system in bad weather conditions

Last edited by a moderator:

anaka

Member

hi people here you can see my fist multirotor BG test

View attachment 12369View attachment 12370View attachment 12371

all is custom made

the video is RAW directly form my GH2 camera, just a little cutting and titles

View attachment 12369View attachment 12370View attachment 12371

all is custom made

the video is RAW directly form my GH2 camera, just a little cutting and titles

Attachments

Last edited by a moderator: