Hey everyone! Excited to post my first build thread. Wouldn't be anywhere without the help of this forum, and people like (@Motopreserve) and more.

After months of scouring and researching for the most cost effective and functional rig for AP/Cinema for work I landed upon the good ole' DJI F550. I'm sure you have seen a million of these, but this is my first time. Read Many mixed opinions, reviews, and comparisons to other bigger & better rigs but this seemed to be my BEST start for the budget & beginner. I will be shooting small (Rx100/GoPro/Nex5). I know nothing about soldering and never have, so hang with me

I know this is something I can search and post separate threads for each component and tiny question, but I decided to keep all of MY questions here for everyone to see as I'm going. Let me have any comments/critique/opinions/No-No's you may know!

Pictures to go along by tomorrow. Right now everything is in a million boxes on my desk ready to work. Also I'm over budget so I'm hoping this is EVERYTHING I need (minus a charger which I'm purchasing this week). Below is my current list of parts, pictures coming along this week!

RIG ASSEMBLY PARTS:

-F550 Frame

-30A ESC's (6)

-2212 DJI Motors (6)

-DJI Landing Gear

-Naza V2 W/ GPS

-FrSky Taranis w/ X8R Receiver

-RMRC 4s 3300mAh LiPo

-HQ 1047 Slow Fly Props (6)

TOOLS:

-Weller 60w "925f" Soldering Iron

-Loctite Red 271 Threadlock

-H20-5 Water Soluble Flux Paste

-7" Wire Stripper/Cutter

-Hobby Knife

-60/40 leaded Solder

ACCESSORIES:

-XT-60 Male/Female Pair (3)

-3.5mm Bullet Connector Male/Female (6 Pairs)

-12ga Wire (Red & Black)

-Assorted Heat Shrink (1.6mm, 4.5mm, 9.5mm, 2.4mm

Thanks for looking!

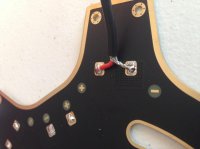

Edit: The picture seems to flip upside down after uploading. Will try a rotation next time

View attachment 17744

After months of scouring and researching for the most cost effective and functional rig for AP/Cinema for work I landed upon the good ole' DJI F550. I'm sure you have seen a million of these, but this is my first time. Read Many mixed opinions, reviews, and comparisons to other bigger & better rigs but this seemed to be my BEST start for the budget & beginner. I will be shooting small (Rx100/GoPro/Nex5). I know nothing about soldering and never have, so hang with me

I know this is something I can search and post separate threads for each component and tiny question, but I decided to keep all of MY questions here for everyone to see as I'm going. Let me have any comments/critique/opinions/No-No's you may know!

Pictures to go along by tomorrow. Right now everything is in a million boxes on my desk ready to work. Also I'm over budget so I'm hoping this is EVERYTHING I need (minus a charger which I'm purchasing this week). Below is my current list of parts, pictures coming along this week!

RIG ASSEMBLY PARTS:

-F550 Frame

-30A ESC's (6)

-2212 DJI Motors (6)

-DJI Landing Gear

-Naza V2 W/ GPS

-FrSky Taranis w/ X8R Receiver

-RMRC 4s 3300mAh LiPo

-HQ 1047 Slow Fly Props (6)

TOOLS:

-Weller 60w "925f" Soldering Iron

-Loctite Red 271 Threadlock

-H20-5 Water Soluble Flux Paste

-7" Wire Stripper/Cutter

-Hobby Knife

-60/40 leaded Solder

ACCESSORIES:

-XT-60 Male/Female Pair (3)

-3.5mm Bullet Connector Male/Female (6 Pairs)

-12ga Wire (Red & Black)

-Assorted Heat Shrink (1.6mm, 4.5mm, 9.5mm, 2.4mm

Thanks for looking!

Edit: The picture seems to flip upside down after uploading. Will try a rotation next time

View attachment 17744

Attachments

Last edited by a moderator: