Yesterday morning I spent some time assembling the camera mount. In preparing to build the X650 I overlooked the fact that I'd need two servos for the mount but I was able to find in my collection of stuff a new/old Tower Hobbies TS-11 servo for the nick function and a Hitec HS-55 for the shutter. The shutter release is a mechanical system comprising a servo with an arm that can be adjusted to reach up and over the camera to rest a nub on the release button. When you throw the switch the servo moves the arm which presses the button. I'm using my wife's Panasonic TZ3 and I was able to program the burst function to take five pics at a rather lazy continuous pace for each press of the button. That'll work for me.

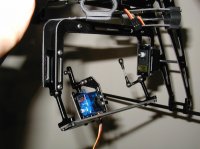

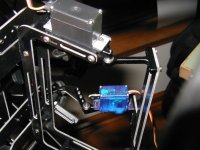

The attached pictures show the nick servo and the little aluminum plates I had to install to have the servo stay tightly in its spot. The holes in the servo mounting tabs were way bigger than the tiny screw that holds it in and there's no room for grommets and such so I just cut and drilled some scrap aluminum I had laying (lieing?

) around. The other two pics show the vibration isolating rubber pieces that the whole mount hangs on as well as the servos that control the mount. I didn't connect the servos to the mount because I want to get the quad and radio fired up before I lock anything in position.

I've got to get the quad configured before I do anything else. It comes from the factory set to operate in the '+' configuration with 3S packs but I've got it set up as an 'x' and I bought 4S packs for it. There's a simple file install that has to be done but I can't get the quad to talk to my computer and it's possibly due to my laptop being run with Windows XP. We're working on it.

Other stuff done today involved swapping out battery connectors to female Deans Ultra since the copter comes from the factory with a male Deans Ultra. I also had to swap out all of the charging/balancing taps on the packs for my Cellpro chargers.

I'll update this in a day or two when I have the software updated and the replacement props installed. It's ready to go and I'm just waiting on those two things.

Happy coptering.

Bart