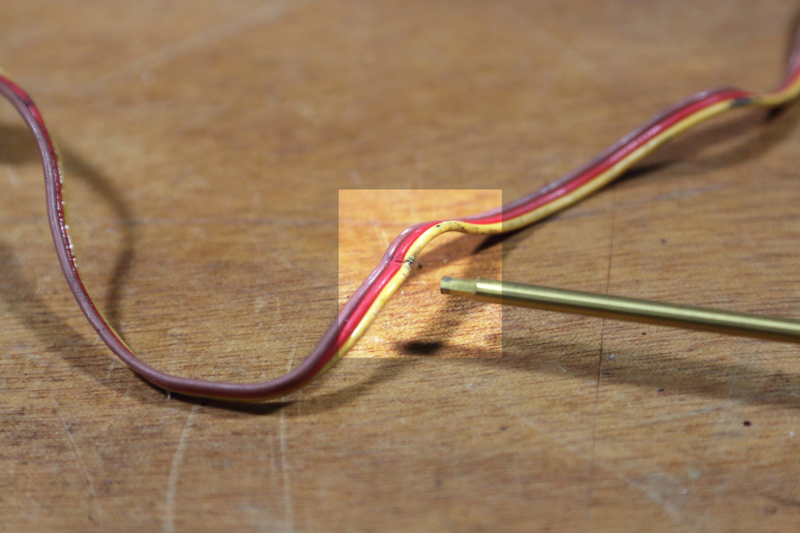

Regarding wires exiting the booms inside the frame. I've had the same issue with wire chafing at the exit opening others have experienced. After becoming fed up with trying to re-fit those grommets I also elected to use some braided sleeve at the exits to protect the wires, but limited the amount of sleeve to just a few inches to the inside of the tube and enough on the other side to reach the PDB. A little tape and a small zip tie on the end inside the boom keeps it fixed.

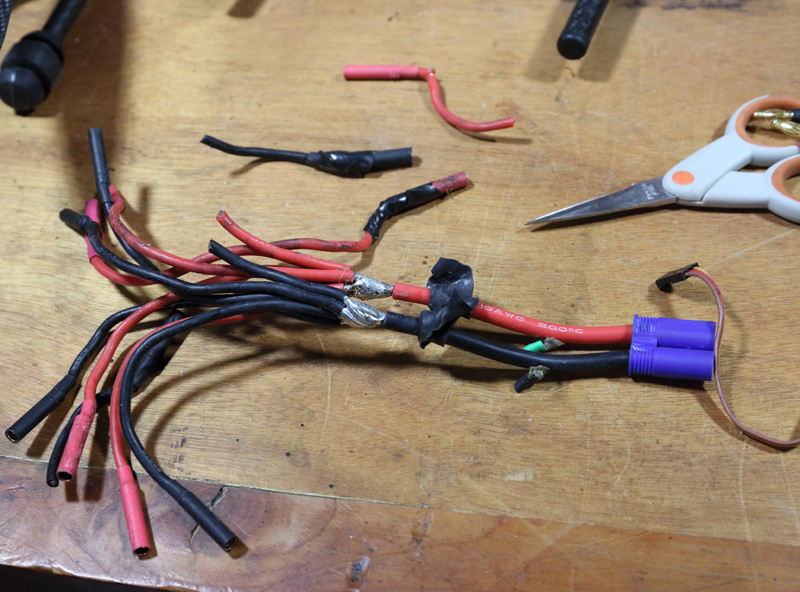

As for accessory power taps, don't make the mistake I made and set up too many. A bunch of loose wires looks bad and is dead weight. After all the work was done I looked back and decided only two accessory taps were necessary, one for 5v and a second for 12v, each having an independent voltage regulator. You can add numerous accessories later to either power buss if only two things are done. One, limit the amount of current that will be drawn through the regulator and, two, construct a power expansion strip of your preference that allows for easy connect/disconnect options. A simple JST breadboard or similar could be made for each voltage lead that possessed as many accessory connection points as your heart desired. That allows easy installation of wiring by plugging in a 2 or 3 pin connector of your choice. Otherwise there's just too much destruction involved in having to expose and un-solder wires every time some little thing reaches end of life or if you want to try something new. There's enough work in fishing wires through small frame openings to make a change as it is.

Your satisfaction with your 810 won't be entirely based on how it performs, which should be good, but also with how user friendly it is in both operation and serviceability. If it flies great but is difficult to work with, or on, you'll end up using it less and less because corrections or alterations are too difficult. With everything you install, and every connection made, consider ease of access for repairs and modification later. The 810 and 910 are great frames and permit a lot of customization with a little thought and effort.

As for location of the front, it ends up however you want it to be when you assign frame type and motor channels in the FC. Batteries were mentioned earlier, using one large one or two smaller ones. Violetwolf mentioned the advantages of using two in providing redundancy but there's another reason for using two; aircraft balance. Moving a single very heavy battery around to balance the aircraft can work both ways, being easy or hard. If you never, ever change payloads a single battery works out pretty well since you design in a single mounting location based on the weight and location of the payload. But if you change gimbals and cameras the weight offsets can become difficult to deal with and a double battery installation could make balancing easier. Options and decisions, part of what makes this fun