Bartman

Welcome to MultiRotorForums.com!!

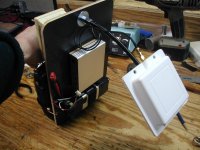

RTRyder asked in another thread about portable receiver set-ups for flying FPV or AP/AV. I had been thinking about my own tripod based set-up and how I didn't love being tethered to something that can't move with me so I got to work on a tray for my radio to which I could also fasten my Rx gear.

I began with a piece of 3/8" plywood and got it to a size I could be comfortable with. I fly with my thumbs only so I didn't want the tray extending much past the radio and rubbing against my knuckles. I'm going to mount the radio to the tray by the metal handlebar which will elevate it off the flat surface so I can still wrap my fingers around the underside when I'm flying. The whole thing will be suspended by my neck strap clipped to the radio's normal strapping spot.

Here are a few pics to get things started.

I began with a piece of 3/8" plywood and got it to a size I could be comfortable with. I fly with my thumbs only so I didn't want the tray extending much past the radio and rubbing against my knuckles. I'm going to mount the radio to the tray by the metal handlebar which will elevate it off the flat surface so I can still wrap my fingers around the underside when I'm flying. The whole thing will be suspended by my neck strap clipped to the radio's normal strapping spot.

Here are a few pics to get things started.