Efliernz

Pete

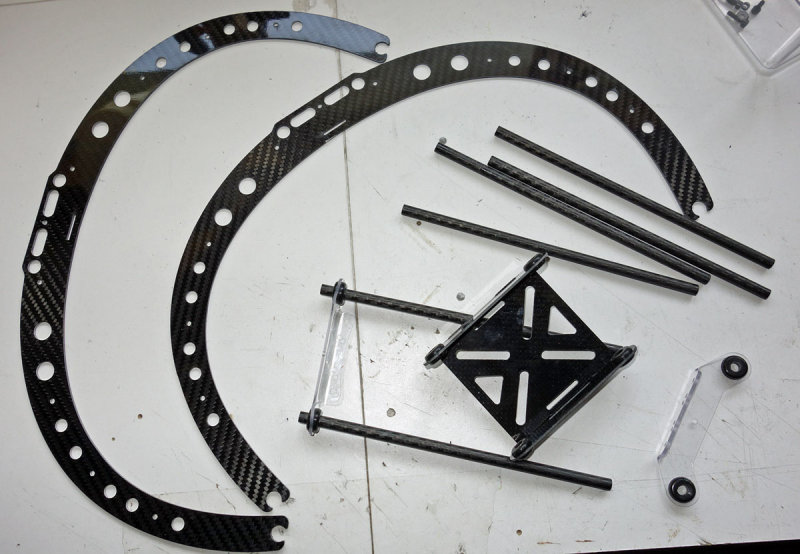

Pete's Droidworx VM-6 Hexa build blog...

I have built about 12 multirotors in the last two years... all diy - most scratch-built, some with X468 parts and my current octo from a "Rustys" hub.

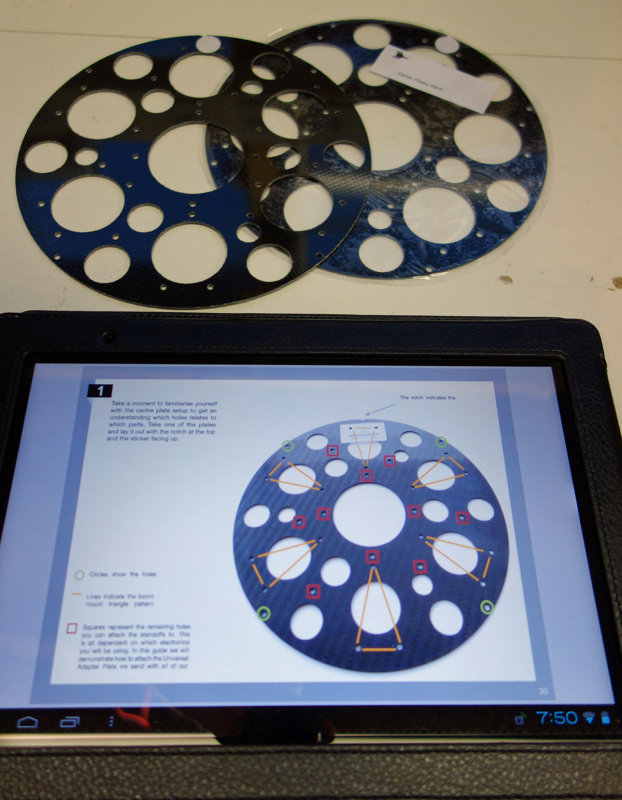

While I do some video (not commercially), my main purpose is to fly a light-weight Sony RX100 for stills photography work. My octo does it now but I wanted something light, strong and new. About a month ago, Droidworx started updating their website and were featuring a new set of machines. The VM series replaces much of the AD series. While I would like a bigger machine, a basic VM-6 should suit my needs. Droidworx are also based only 40Km from me so postage wasn't an issue and I knew that support is literally "just around the corner".

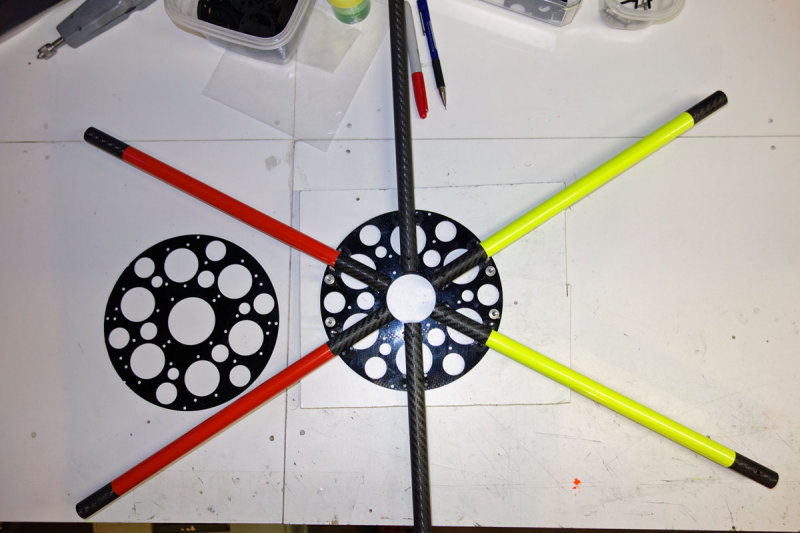

I am already flying a quad with Sunnysky 2814 700Kv 120 gram motors. They are not Axi's... but "good budget motors". They are at the top limit of what should be on this size hexa, so six were ordered.

Why a hexa? My 770mm octo gets blown around in the wind more than my old heavy experimental hexa did - so a hexa it is. Orientation is also easier.

My current fleet:

I have built about 12 multirotors in the last two years... all diy - most scratch-built, some with X468 parts and my current octo from a "Rustys" hub.

While I do some video (not commercially), my main purpose is to fly a light-weight Sony RX100 for stills photography work. My octo does it now but I wanted something light, strong and new. About a month ago, Droidworx started updating their website and were featuring a new set of machines. The VM series replaces much of the AD series. While I would like a bigger machine, a basic VM-6 should suit my needs. Droidworx are also based only 40Km from me so postage wasn't an issue and I knew that support is literally "just around the corner".

I am already flying a quad with Sunnysky 2814 700Kv 120 gram motors. They are not Axi's... but "good budget motors". They are at the top limit of what should be on this size hexa, so six were ordered.

Why a hexa? My 770mm octo gets blown around in the wind more than my old heavy experimental hexa did - so a hexa it is. Orientation is also easier.

My current fleet:

Last edited by a moderator: