kloner

Aerial DP

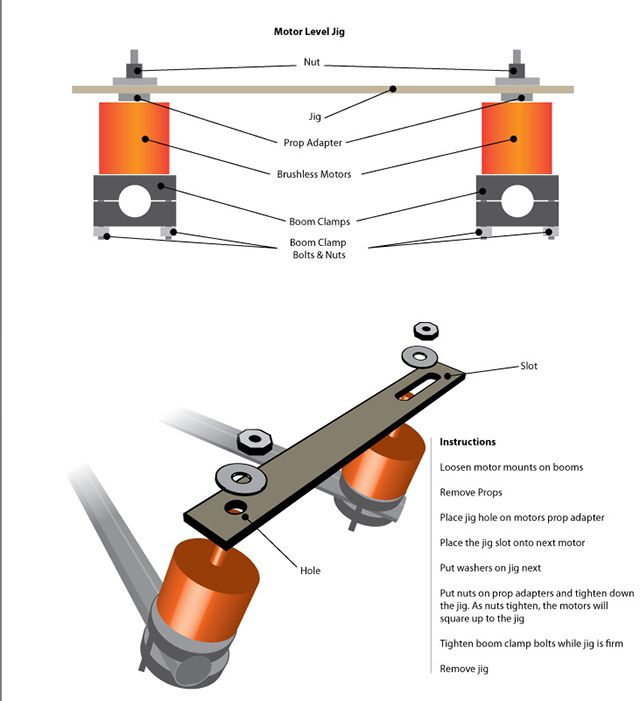

What are different tricks and tips to getting motors on round booms "just right" ? It's not like it's just a set it and forget it thing traveling and all. is there any precise ways to make it a one time thing? anybody ever pin a boom with a screw so it has one position to sit? all my big helicopter tails had that done, more so it couldn't twist if it loosened up

Last edited by a moderator: