Maymidroix

Member

Hi everyone,

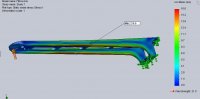

I'm a senior mechanical engineering student and I started flying multirotors early this year. I bought a DJI flamewheel 450 becuase it was very cheap and found that it was a good frame to start into multirotors. Something that I hated about it was that on every small crash that I had, the arms broke. Then I had to spend about 20 to 30 minutes replacing the plastic arms. Yes, the plastic arms a very cheap but spending that much time replacing the arm was a waste of time for me. So I thought about designing an aluminum arm that will not break or get damaged as easily as the stock arms. Having that in mind, I designed these aluminum arms. The are made using CNC machining and will have red and black anodized finish for orientation. They fit perfectly on the frame plates, they have the same thread size as the stock ones, so no modification is needed. They are 50mm longer to improve the flight stability. I added 3 holes on the motor side to have the option of adding a second motor mount for an X8 configuration.

View attachment 13399View attachment 13400View attachment 13401View attachment 13398

Luckily, I was living very close from the warehouse of ReadyMadeRC. I went there with my computer and showed my design to Tim (owner of readymaderc), and he like it, so he agreed to sell them.

Here are some pictures of the prototype arms on my quad:

View attachment 13402View attachment 13403View attachment 13404View attachment 13405View attachment 13406View attachment 13407View attachment 13408

On the first flight with the arms I noticed the improvement in stability and control because of the extended length of the arms and because they are very stiff.

After about 2 months since I had the idea, they are now posted in www.readymaderc.com http://www.readymaderc.com/store/index.php?main_page=index&cPath=76_155 They'll be in stock in about 2 weeks so you can pre-order them now. I only made an small batch so they might sold out fast.

Please give me your feedback about this.

Thanks,

Michael Maymi

I'm a senior mechanical engineering student and I started flying multirotors early this year. I bought a DJI flamewheel 450 becuase it was very cheap and found that it was a good frame to start into multirotors. Something that I hated about it was that on every small crash that I had, the arms broke. Then I had to spend about 20 to 30 minutes replacing the plastic arms. Yes, the plastic arms a very cheap but spending that much time replacing the arm was a waste of time for me. So I thought about designing an aluminum arm that will not break or get damaged as easily as the stock arms. Having that in mind, I designed these aluminum arms. The are made using CNC machining and will have red and black anodized finish for orientation. They fit perfectly on the frame plates, they have the same thread size as the stock ones, so no modification is needed. They are 50mm longer to improve the flight stability. I added 3 holes on the motor side to have the option of adding a second motor mount for an X8 configuration.

View attachment 13399View attachment 13400View attachment 13401View attachment 13398

Luckily, I was living very close from the warehouse of ReadyMadeRC. I went there with my computer and showed my design to Tim (owner of readymaderc), and he like it, so he agreed to sell them.

Here are some pictures of the prototype arms on my quad:

View attachment 13402View attachment 13403View attachment 13404View attachment 13405View attachment 13406View attachment 13407View attachment 13408

On the first flight with the arms I noticed the improvement in stability and control because of the extended length of the arms and because they are very stiff.

After about 2 months since I had the idea, they are now posted in www.readymaderc.com http://www.readymaderc.com/store/index.php?main_page=index&cPath=76_155 They'll be in stock in about 2 weeks so you can pre-order them now. I only made an small batch so they might sold out fast.

Please give me your feedback about this.

Thanks,

Michael Maymi

Attachments

-

BESTarmview.JPG127.1 KB · Views: 1,057

BESTarmview.JPG127.1 KB · Views: 1,057 -

EVOTEK ARM 1.JPG42.2 KB · Views: 1,015

EVOTEK ARM 1.JPG42.2 KB · Views: 1,015 -

EVOTEK ARM5.JPG82.3 KB · Views: 907

EVOTEK ARM5.JPG82.3 KB · Views: 907 -

EVOTEK ARM6.JPG82.9 KB · Views: 945

EVOTEK ARM6.JPG82.9 KB · Views: 945 -

20130810_103243.jpg146.3 KB · Views: 1,096

20130810_103243.jpg146.3 KB · Views: 1,096 -

20130810_130438.jpg146.4 KB · Views: 1,043

20130810_130438.jpg146.4 KB · Views: 1,043 -

20130810_130447.jpg146.6 KB · Views: 881

20130810_130447.jpg146.6 KB · Views: 881 -

IMG_5275.jpg142.4 KB · Views: 1,061

IMG_5275.jpg142.4 KB · Views: 1,061 -

IMG_5276.jpg144 KB · Views: 1,206

IMG_5276.jpg144 KB · Views: 1,206 -

IMG_5277.jpg128.6 KB · Views: 978

IMG_5277.jpg128.6 KB · Views: 978 -

IMG_5280.jpg133.7 KB · Views: 1,099

IMG_5280.jpg133.7 KB · Views: 1,099

Last edited by a moderator: