I got the dreaded "Bad Gyro Health" message with my Hobby Works HK v2.5. My first mistake was buying the HobbyKing board. These things are junk. Terrible solder joints, bad lamination....junk. I should have spent the extra couple of bucks and got the board from 3DR. I haven't even flown the craft yet, and the second time I plugged it in, I got the message on the Mission Planner.

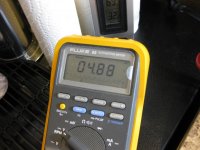

After some research, It turns out that the latest firmware can smoke one of the voltage regulators, or the regulator was defective to begin with and the firmware is now "noticing" it. This seems to be happening mostly on clone boards. When the regulator fails, you will have a full 5 volts running your sensors instead of the regulated 3.3 volts.

According to the 3DR website, your only options are to send the board back or replace the regulator. Since this is a HobbyKing product, I don't think it is worth trying to deal with their customer service...

The good news is these tiny regulators are only about $1.50 from Digi-Key

http://www.digikey.com/product-detail/en/TPS79133DBVR/296-11866-1-ND/381441

I was able to fairly easily get the old one off with a small Radio Shack soldering iron. I should be getting the new regulator in the mail in a day or two, so I will follow up if I can successfully get it back on the board. View attachment 15450View attachment 15451

I'm curious to see if the voltage regulator on the HobbyKing board was the correct Texas Instruments regulator, or some kind of China copy.

After some research, It turns out that the latest firmware can smoke one of the voltage regulators, or the regulator was defective to begin with and the firmware is now "noticing" it. This seems to be happening mostly on clone boards. When the regulator fails, you will have a full 5 volts running your sensors instead of the regulated 3.3 volts.

According to the 3DR website, your only options are to send the board back or replace the regulator. Since this is a HobbyKing product, I don't think it is worth trying to deal with their customer service...

The good news is these tiny regulators are only about $1.50 from Digi-Key

http://www.digikey.com/product-detail/en/TPS79133DBVR/296-11866-1-ND/381441

I was able to fairly easily get the old one off with a small Radio Shack soldering iron. I should be getting the new regulator in the mail in a day or two, so I will follow up if I can successfully get it back on the board. View attachment 15450View attachment 15451

I'm curious to see if the voltage regulator on the HobbyKing board was the correct Texas Instruments regulator, or some kind of China copy.